From left, Graeme Jones (production director), Graham Wheeler (director of innovation) and James Lawson (managing director)

Now 20 years old, The Real Petfood Company has hit a number of milestones – including Wagg’s debut into wet dog food. MD James Lawson and TRPC founder Graham Wheeler give pbwnews a look behind the scenes at the Welsh multi-million pound facility

There is a tangible buzz at The Real Petfood Company (TRPC) in North Wales, and not just because it is making Wagg’s first-ever wet dog food which rolled out into stores at the end of January. The buzz arises from the instinctive impulse to innovate, a momentum that is driven by its MD James Lawson and TRPC founder Graham Wheeler, both of whom are firmly committed to using the freshest-possible ingredients and ‘keeping things simple’.

James, who prefers to use the phrase ‘co-products’ rather than ‘by-products’, said: “We do very high-quality, premium products. Pets are now family, and so we use co-products, which are human-grade quality food. Higher-quality ingredients and products are coming on to the market all the time, and there is a strong focus on ‘back to nature’ in terms of fresh, real ingredients.

The firm’s 50,000sq ft finished products storage area

“I want to drive the whole industry forwards and towards fresh and just as we want for our families, I will be pushing for more real meat, real fruit and vegetables in our products.”

There is much research going on into biologically active factors in fresh food – in short, ingredients that offer some kind of functional benefit. “If you cook them carefully, they are transferred through the food,” he said. “Nutritionists will be learning about this for hundreds of years to come.”

As for keeping things simple, this stems from the public’s growing distrust of some of the big multinational names. “People are moving towards taking things back to basics,” he said. “Which is why there is such growth in premiumisation and natural pet food, because a lot of people are saying they do not trust big – or understand it, for that matter. It’s almost an emotional response to ‘If it’s simple, I can trust it’.

“Take raw, it’s very simple and is the whole ‘back to nature’ and the natural part of the market.”

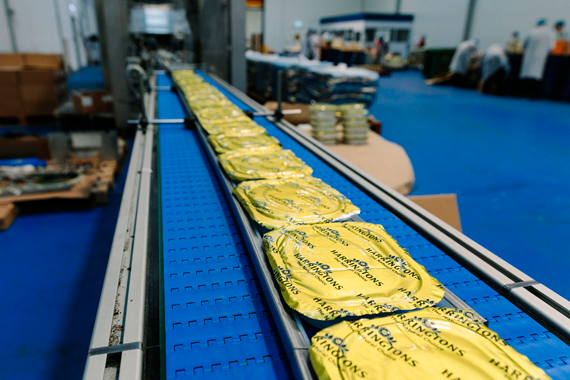

Harringtons’ wet dog food trays in production

Wet, wet, wet

James has a very long history in the pet and animal food sector (his early days were spent on pig nutrition), and for years wanted to explore the wet pet food category.

“I researched what is good wet and what is bad wet, and visited some factories around the world,” he said, which led him to identifying best-in-class manufacturers and practice.

Harringtons’ wet dog food trays on the production line

His break into wet finally came when he joined Inspired Pet Nutrition in July 2018 and became MD of daughter company TRPC, which began making Harringtons wet food.

There is so much misinformation about wet, he said – many people think wet uses human-grade ingredients that are cooked from fresh, but instead, many manufacturers use pre-cooked ingredients. “They used these cooked ingredients and put them into a can and then cook it again – yet the market has not had to explain this. It’s about time that the consumer can understand a bit more about this.”

At TRPC, its wet Harringtons and Wagg foods are neither over-cooked nor double cooked. “We have not destroyed the nutritional value of our ingredients,” he said. And because of its cooking methods, TRPC can ensure ‘really great aromas and palatability’.

Quality checks occur at every stage of production

Freshness is guaranteed with ingredients arriving from as local as possible, typically within a 100-miles radius. One of the advantages of the UK is its ‘fantastic agricultural sources’, he said, from its meat and poultry to abundant fish, including ‘great cod, haddock and whiting’.

TRPC’s wet food is a major focus of investment, and while current capacity could achieve 20-25,000 tonnes, there is enough room for expansion to achieve 100,000 tonnes.

Do it better

Inspired Pet Nutrition, formerly known as Wagg Foods, was set up in 1923 when the current directors’ grandfather set up an animal feed mill, Page Feeds, in North Yorkshire. The Eighties saw the launch of a dry dog food and by 1990, the business switched from animal feed to pet food, changing its name to Wagg. In 2016, it became known as IPN and for some years now has been the UK’s largest independent producer of dry pet food.

Snacks production underway at The Real Petfood Company

Yet at its heart are its Yorkshire roots and the work ethic of the Page family. James said: “That vision from the Page family has been to take the frugal British Yorkshire characteristic of saying ‘we can do it, do it ourselves, better than others and at better value’. That’s the core part of IPN’s DNA and success.

“We are a UK-based owner and manufacturer of brands and own-label, and we offer nutritionally superior food and work really hard at supplying that excellence in our products, ingredients, the whole operational process, and then offering it to the market. We offer superb value for money; it’s a proven model for IPN and our plan is to continue with that.”

The business is also committed to investing ‘in more fresh ingredients than anyone else’, he said. “We are about nutritionally superior products that we offer in an affordable and accessible way.”

The Real Petfood Company was set up in 1998 as a pet treats and snacks manufacturer, and Graham recalls those early days and how one of its first treats was for the equine market.

Getting ready to ship Wagg treats out

Yet even in those early days, there was a strong emphasis on natural and the use of, for example, natural colouring. TRPC soon counted Wagg as a customer, and then German pet chain Fressnapf placed a large order for one of its core treats ranges that would, in effect, double its production overnight.

Graham said: “By faith or good fortune, Wagg decided at that same time that they wanted to get into the manufacture of treats and snacks.”

Investment followed and TRPC came under the umbrella of Wagg and embarked on a period of expansion, moving to a new 15,000sq ft site in Flint in 2008. Eight years later, TRPC moved again, this time 15 miles away to an 150,000sq ft site in Bodelwyddan, Denbighshire, at a cost of £6m.

“Our previous place was full to the brim,” said Graham, with production at full capacity. In 2014, turnover had grown from £500,000 to £3-4m. Last year, it hit £7m and turnover is expected to continue its strong growth this year.

Harringtons products are sold across the country

Crucially for Graham, the new site saw the installation of a high-output, continuous baking line compared to the smaller-scale batch system it had been using at Flint. While a traditional commercial oven is 160-metres long, TRPC’s continuous oven is compressed into 25 metres but with a conveyor belt looping around 13 layers, each of which can be independently regulated temperature wise to allow for efficient baking and cooling.

“People used to say that baking was too expensive,” he said, but now he’s managed to realise a long-held dream.

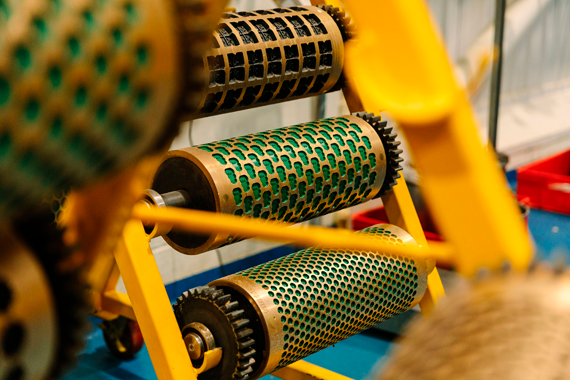

Moulding rollers help produce a wide range of shapes in treats and snacks

Investment at the Bodelwyddan site into both its wet and baking facilities has hit £14m, but that is forecast to see healthy results and turnover by 2028 is projected at £50m, with wet food forecast to take in pole position.

Best of both worlds

TRPC is home to another one of Graham’s dream projects, the baked dog food and treats brand Nineteen 87, named after the year he began in the pet food industry. The beauty of Nineteen 87, he said, is that its recipes are simple and the products use 50% fresh meat, fish or poultry, all sourced from UK farms.

Robotic equipment helps speed up production at The Real Petfood Company

Repeat purchases of Nineteen 87 are fantastic, said James, and once trialled; its ‘natural palatability’ drives sales. “The challenge is driving that trial and getting more shops involved with it,” he said.

“Like for like with similar products, it performs fantastically and has this natural aroma from the fresh ingredients, not lots of sugar coating.”

Baking as a cooking method is also gaining traction and ‘interest in baking is very apparent’ as consumers become more aware of the gentle cooking process compared to extrusion. All indications are that demand will continue to rise for baked food and treats. TRPC also supplies own-label and is currently working on new baked recipes for some of its clients. Own label is an exciting area, said James, as it means constantly exploring with the freedom to develop new recipes. He said: “Our own-label partners can put certain demands on you to develop new products, but it is useful to have this outside influence as it pushes you on to new ideas and you are challenged.”

Wet food (made inhouse as well as competitor offerings) are duly checked for quality and appearance

With 450 ingredients to hand, the sky’s the limit as far as recipes are concerned and they can experiment with different variables – simple factors like adding ingredients in a particular order or at a different temperature will impact and affect the look and quality of the final product. It’s all about research and development to achieve the best result.

Looking ahead

Automation is high on the agenda at TRPC, said James, and there are plans to invest in more machinery and training for staff. At the moment it employs 65 staff, but this figure could potentially grow to 150. TRPC is committed to growing a skilled labour force and has an active training programme, including the provision of apprenticeships. The aim is for a multi-skilled workforce with transferable skills ‘for the good of the industry’.

He said: “If you are excellent at what you do, you can compete on a world level and we can operate here just as efficiently as other facilities around the world.”

Finished products are held ‘in quarantine’ for two weeks before shipping out

There is also significant focus on innovation and new products within the IPN brands – and there might even be new brands, he said. Cat food also presents opportunities, said James. “There will be lot of future investment, and lots of trends we have spotted, but with a fresh angle.”

One area James is particularly intrigued with is bone broths for pets, which are now on sale in the States and have been on show at trade shows there. He said: “I go to Global and I see what’s being launched, what’s got more prominence and then think about it, whether there’s something in it or if it’s a gimmick. Bone broth, there’s something in it…but not just bone broth, you also need the right ingredients and cooking method.

“I make my own soups at home – I try and cook when I can, for example, roast chicken, and take the bones and make soup. But I also whizz up vegetables in it, and we call it ‘Super Juice’. And my kids love it.”

The next 12 to 24 months will therefore see more focus on the use of human-grade ingredients across baked, wet and dry ranges, ‘more premium products and real visual ingredients, real texture, maybe a broth-based soup’.

Convenience is also going to drive innovation. “The way that food is presented, collected and delivered, and even consumed on the go, these will all have an impact,” he said. “We have to be agile and develop solutions that fit within the brand. Being agile is important as markets do change.”

The issue of recycling is just one way that the market has changed, and TRPC’s wet food trays were switched from black to white so they can be recycled at recycling centres.

With so much going on and plans for the future, there is never a dull moment. Graham said: “It’s exciting times. In a way, it’s like going back to my early days, but now there is a team to work with and bounce off ideas.

The company has made a huge investment over the years, and I want to see this site working like we did at Flint, with proper efficiencies and up to speed at full capacity.”

At the moment, the warehouse can hold 3,500 pallets

Eyeing up exports

At the moment, exports represent less than 1% of IPN’s turnover.

“If it was easy, everyone would be doing it,” said James.

“We need the right product with the right ingredients at the right price, in the right position with the right strategy. Yet I see UK plc. being very attractive in terms of export potential. But you cannot just fly out to Japan and say, ‘Buy our product’.

“A lot of people around the world do wet and dry food, but not everyone can be as innovative as the UK.

However, for us there is still quite a lot to do in the UK, and we have to build the market and foundation for export.”

He believes Harringtons and Nineteen 87 could be ‘extremely attractive’ for the export market, and it is only a matter of time before IPN has a more aggressive export strategy.

What’s that smell?

In all the years spent at Flint making pet food and treats, not once did issues of odour crop up. But at Bodelwyddan, the local topography led to a situation where smells were pulled downwards and towards the neighbouring housing estate.

James said: “When we make, for example, our apple and cheese flavour, well, it smells a bit like apple and cheese outside. Some people are not bothered and other people do not want that smell, and I get that.

“You need to make sure you are not exposing people to it when they did not ask for it.

“We have done a lot of work in terms of getting the scientific solution to resolve the issue, and we need to make sure we are doing our best so that we do not become a nuisance to our neighbours.”

The council has approved plans for a 35-metre chimney to dissipate odour into the air, and TRPC will also plant trees along the perimeter as a screen.

“We have been criticised for dragging our feet, but there is a due process that we had to follow,” he said, adding that the chimney should hopefully be built and operational by the summer. ”

We are a business trying to do our best and putting correct procedures into place.”

There is ample room inside the facility for expansion